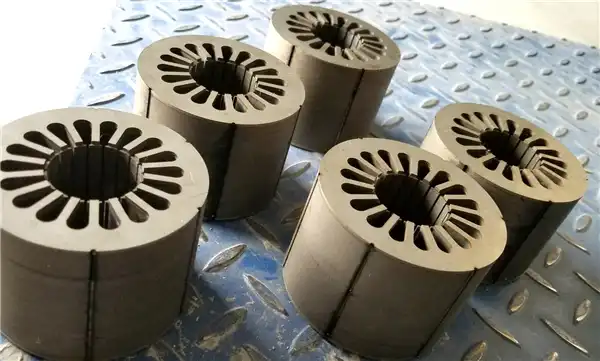

Electrical engineers want to design more efficient motors that minimize the iron loss of the motor, including the iron loss of the stator core. Youyou technology's motor iron core glue bonding technology eliminates this difficulty. The bonded iron core exhibits optimum thermal conductivity, has no harmonic noise, and does not change with temperature changes. Also, interlayer corrosion is avoided.

Generally, our motor core lamination technology is mainly divided into the following 3 types:

Punch out stacking riveting points with a certain geometric shape on the appropriate part, most of which are concave holes in the upper part and convex parts in the lower part, and then embed the convex part of the previous punching piece of the same size into the concave-shaped hole of the next punching piece, achieve the purpose of tightening the connection. In the process of forming the iron core, the convex part of the stacking riveting point of the previous sheet should be correctly positioned on the blanking station.

Stack the laser/stamped single-piece silicon steel sheets neatly, and then use laser welding. This technique is usually used for trial production at the sample stage.

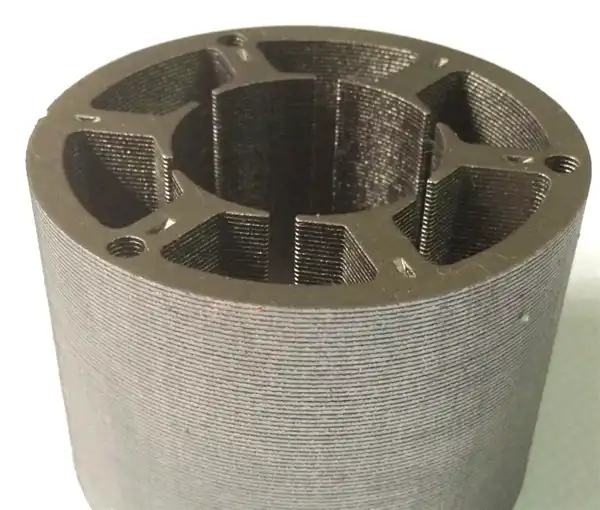

The laser/stamped single-piece silicon steel sheet is coated with varnish or epoxy resin on both sides, and then stacked, equipped with a clamp, applied with a certain pressure, and cured to obtain a perfect iron core. This method avoids short circuit between silicon steel laminations for better electromagnetic performance.

For more details on more bonding technology, please feel free to Contact our team.